Extrucolor was born in the world of aluminum in the last third of the 20th century (1973).

In that year, the "SKYLAB" satellite was launched, the first U.S. space station, and it also coincided with the establishment of the Ford factory in Spain (Ford-Spain), becoming the most important reference for our company. We lacquered all the aluminum rims of their vehicles manufactured in Spain for over 6 years.

In the city of Orihuela (Alicante), a 3000 m2 warehouse was built to set up an aluminum workshop with the aim of manufacturing windows, balconies, and lightweight aluminum facades for construction: Policolor, the embryo that would give rise to the current Extrucolor.

In 1975, the facilities were expanded with an aluminum coating plant, making it the first company in Spain and one of the first in Europe to use the electrostatic coating process for aluminum. This is how Ford-Spain became a client.

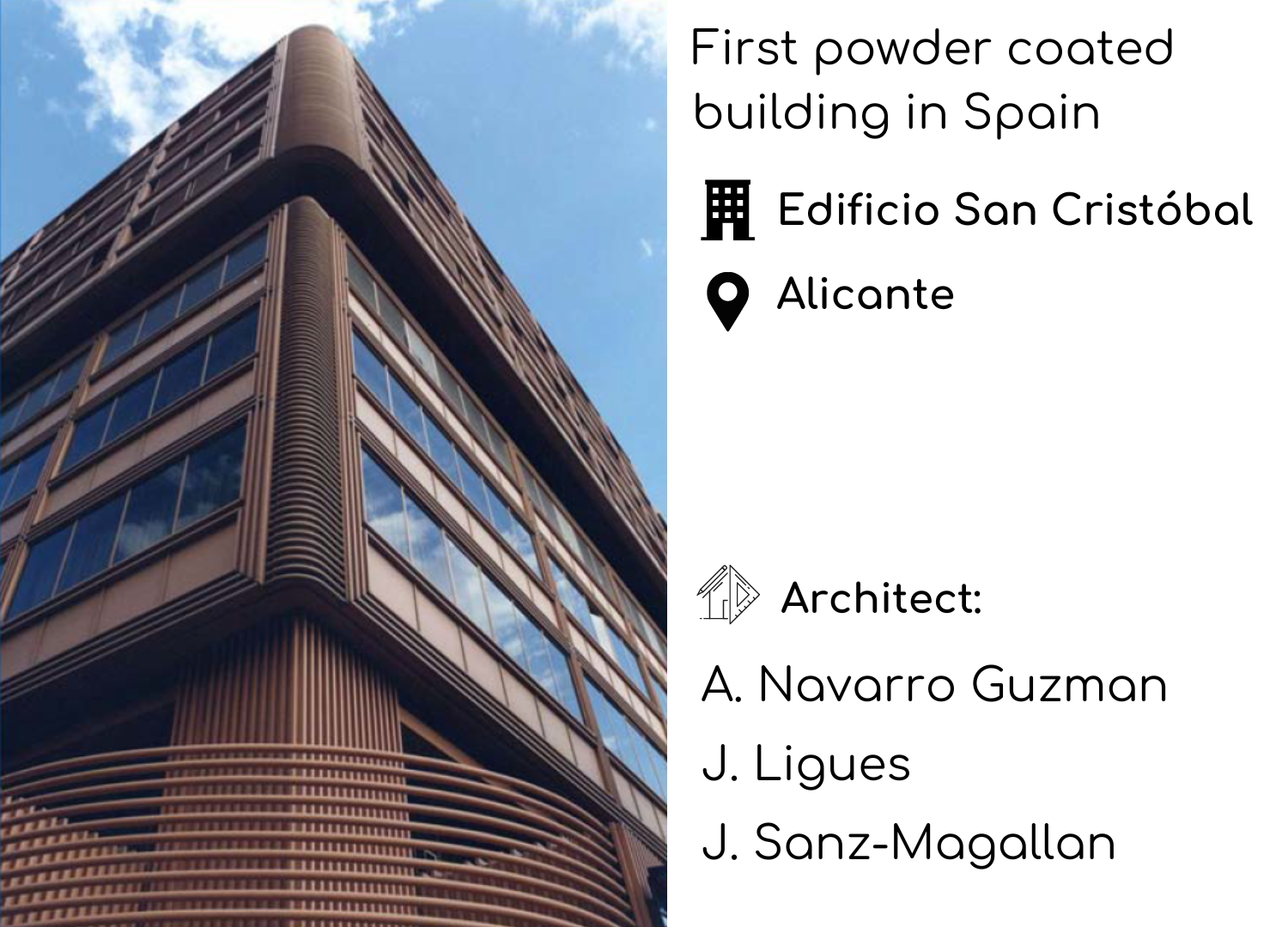

In that same year (1975), we contributed to the first powder coated building in Spain, the "San Cristóbal Building" in the city of Alicante. The entire aluminum facade was manufactured and powder coated in the RAL 3012 color. At that time, it had a significant impact on the industry due to the use of powder coated aluminum in carpentry and facade, leveraging the ductile properties of aluminum and the lacquer's resistance to corrosion.

This building played a pivotal role in the definitive launch of the use of powder coated aluminum for the times to come.

In 1996, 30,000 m2 were acquired in the industrial estate of Abanilla (Murcia). 5,000 m2 were constructed, and an extrusion press of 1,800 tons was installed. This marked the birth of EXTRUCOLOR. Additionally, aluminum warehouses were established for the distribution of the "CONTINENTAL" carpentry system in Tarragona, Castellón, Valencia, and Murcia.

In 2006, 12,500 m2 were built for the installation of a 2,800-ton press and an anodizing plant with a capacity of 58,000 A.

With the incorporation of the 2,800-ton extrusion press, we expanded the capability to extrude larger profiles, enabling us to engage with other sectors that require profiles of larger dimensions. The anodizing plant not only anodizes finishes such as silver, stainless steel, bronze, gold, and black but also broadens the color range through electrocoloration and interference. Additionally, both cold and hot seals are applied, all under the Qualanod quality certification.

In 2016, a high-tech machining center with 5-axis numerical control and a length capacity of up to 15 meters was acquired. This allows for drilling, milling, threading, countersinking, cutting, and angled operations.

Since the beginning, we have had an assembly line for thermal break profiles, with thermoplastic polyamide UNE-EN-14024, crucial for minimizing thermal conductivity and reducing CO2 emissions, which is particularly important today.

At present, EXTRUCOLOR has a total of 40,500 m2 of covered space dedicated to the production, treatment, and distribution of aluminum. This enables us to be present in more than twenty market sectors and engaged in a policy of national and international expansion.